Emirates International University

Modernity

Distinguish

Student graduation projects for the Mechatronics Engineering Department for the academic year 1444 AH.. 2022-2023 AD.

Project No. 1:

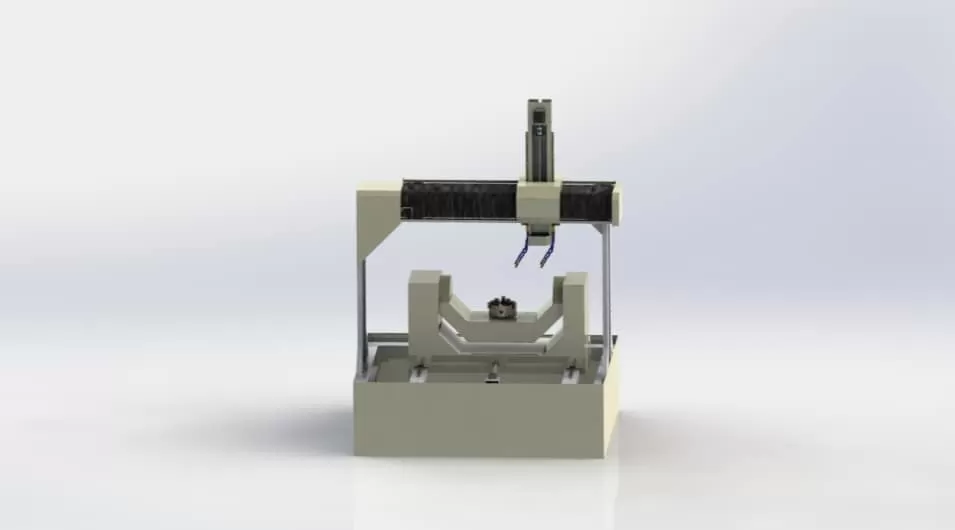

An industrial machine (Machine Axis-5 CNC) that carves and shapes iron. And ready for production with dimensions up to (2m x 2m x 1.8m)

Stages of work on the project:

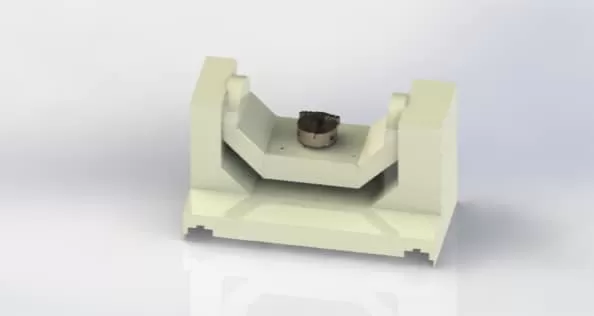

A miniature model of the project was implemented using Arduino due to its cheap price, in order to understand the mechanism of operation of 5-axis CNC machines.

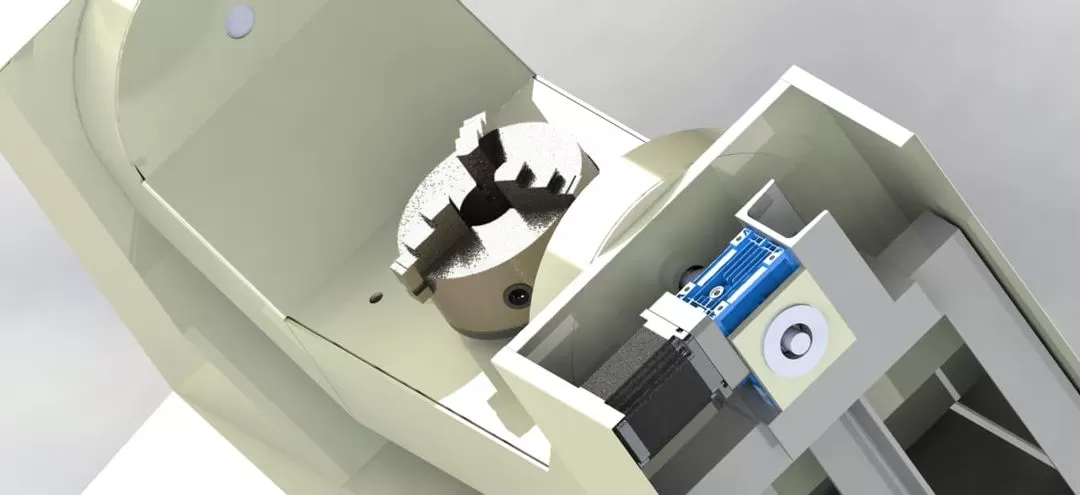

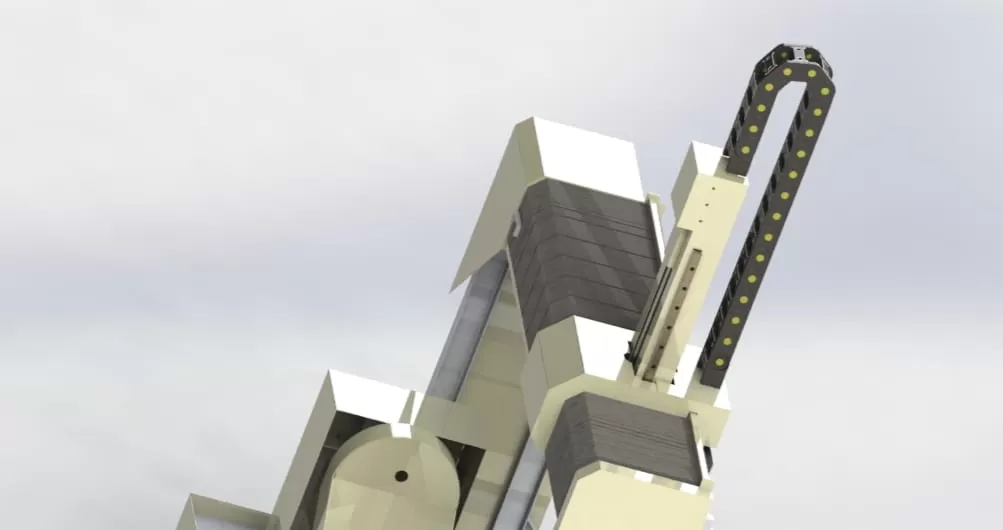

Machine design in "CAD format" in "Solid Work" program.

Motion kinematics simulation in PowerMill.

Dynamics simulation in MATLAB.

Deducing mathematical equations of motion.

Correcting parameters to reach the desired values.

CAM work for all CAD parts and then manufacture them.

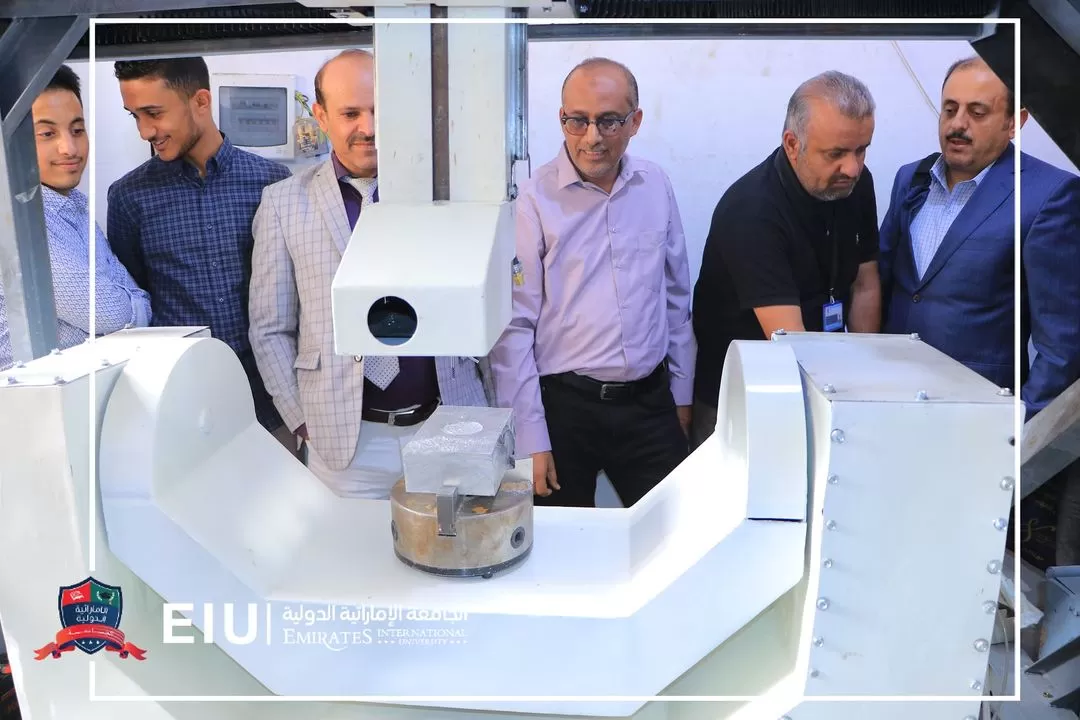

Assembling parts produced from lathes, CNC and plasma machines.

Preparing the “Power mill” program to generate the path of the five-axis cutting tool, and then creating a “post processor” dedicated to the machine that works to link the “CAM” programs and the machine

Finally

Coordination between the “mach3 5axis breakout board” controller and the mach3 program and adjusting its settings

Importance:

5-Axis CNC machines are considered one of the most important tools in modern manufacturing, as they are used in most industries, including military ones such as weapons.

. Advantages:

The machine generates the path of the cutting tool using artificial intelligence technology to avoid the cutting tool colliding with machine parts.

. These machines are characterized by their ability to move in five axes, including the movement of the main axes X, Y, and Z, and the movement of rotation around two additional axes (A and C).

. These additional movements allow the machine to manufacture pieces with intricate shapes, sizes, and details, which increases cutting accuracy and reduces human error.

These machines allow manufacturers to manufacture precise and complex parts in a fast and efficient manner.

. Producing pieces with non-traditional shapes, such as complex geometric shapes, difficult curves, uneven surfaces, iron molds...etc.

. They are used in various industries such as automobiles, aviation, aerospace, medical instruments, electronics, weapons, etc. These machines also help manufacturers to improve product quality, reduce manufacturing time, and reduce costs.

The project is supervised by Dr. Hatem Al-Dais and Engineer Saad Al-Balta. The discussion committee: Dr. Nasser Al-Moufari, Dr. Fouad Hanash, Dr. Muhammad Al-Alfi, Dr. Radwan Al-Bathiji and Dr. Mahmoud Al-Tuwaiti.

#Emirates_International_University

#Modernityanddistinction

#eiu